Vaquita 3.0 Design Rationale

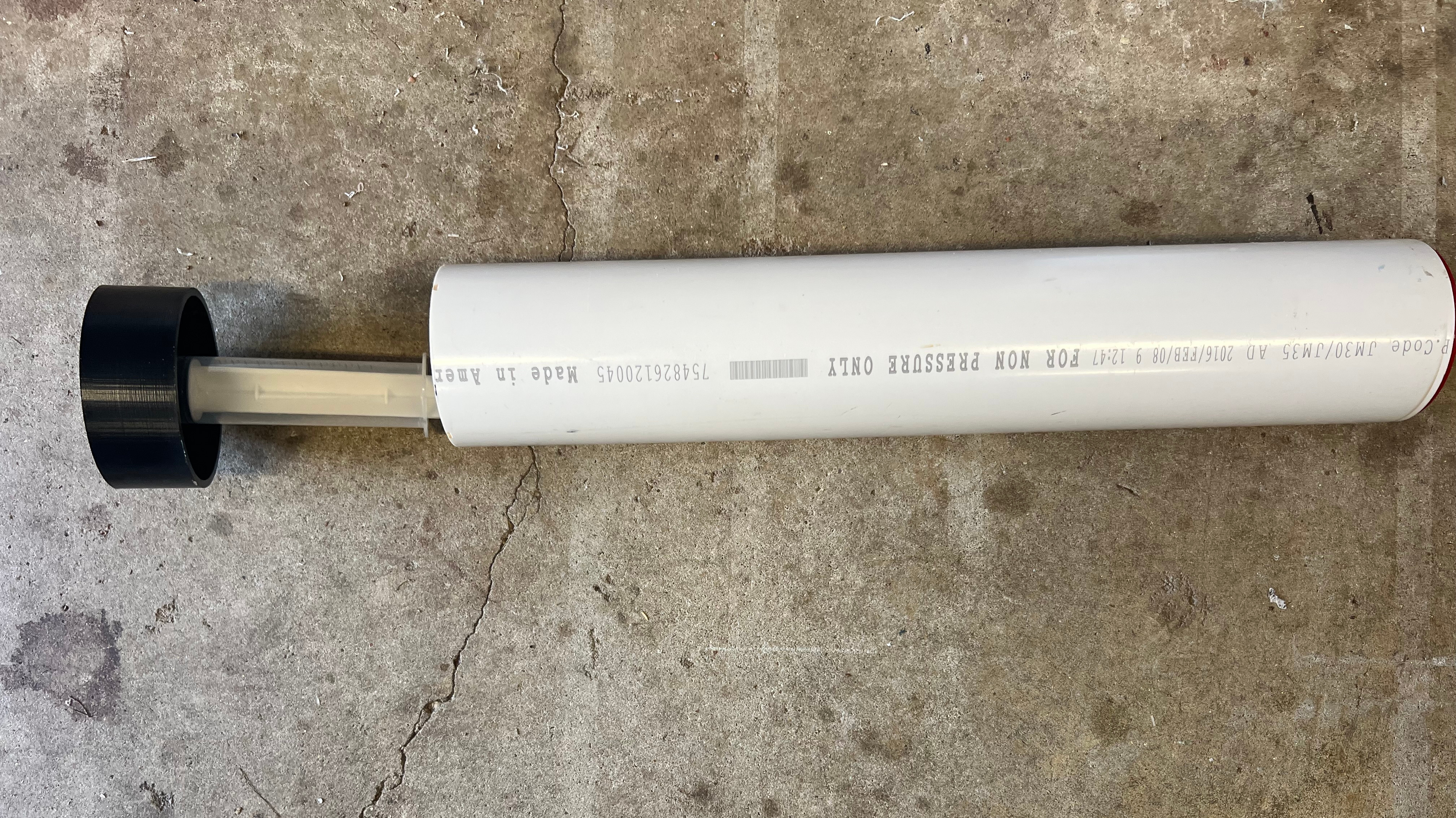

Frame

This year, the GEARS robotics team has assembled the Vaquita 3.0 for the Ranger class MATE ROV Competition. PVC pipes and connectors make up the main structure of the ROV because they are lightweight, cost-effective, and provide flexibility in design. This pressure-resistant material creates a robust rectangular frame to which all components of the vehicle are mounted.

Movement

The Vaquita 3.0 utilizes six Blue Robotics thrusters to facilitate its movement. These powerful, water-resistant thrusters can generate up to 24.5 newtons of force. Two are positioned vertically on the top of the vehicle’s frame, allowing it to ascend and descend smoothly. The remaining four thrusters are located on the corners of the vehicle and provide horizontal movement. Their 45° angled placement allows the vehicle to swivel in place or move in any horizontal direction without needing to rotate. These six thrusters give the Vaquita 3.0 enhanced maneuverability and speed, especially when observing shipwrecks or investigating invasive species.